Extra 5% OFF with Credit Card 💳 | Use code: CARD5

Extra 5% OFF with Credit Card 💳 | Use code: CARD5

Apparel

Accessories

Check out our full lineup of yoga accessories to help you with your daily meditation practice and fitness goals...

Try our new Cork Yoga Brick for soft but solid support

Check out our full lineup of yoga accessories to help you with your daily meditation practice and fitness goals...

Shop

Mega menu

tetasidjaslkihsdlkjfhsdf gjkhsdfgjklsdhfgjkl shdfgjklhsdfgjkl hsdfjklg hsdfkjlg hsdfjklg hsdfjkl ghsdfjkl ghsdfjklgh

Mega menu

Time to get excited about our new collection for Men!

tetasidjaslkihsdlkjfhsdf gjkhsdfgjklsdhfgjkl shdfgjklhsdfgjkl hsdfjklg hsdfkjlg hsdfjklg hsdfjkl ghsdfjkl ghsdfjklgh

Why a Billet Differential Cover Is a Smart Upgrade for Your BMW E30

April 14, 2025 3 min read

The Hidden Weak Point in BMW E30 Rear Differentials

BMW’s E30 platform is beloved for its mechanical simplicity, balanced chassis, and timeless design. But like any vehicle engineered in the 1980s, some components start to show their limitations under modern use—especially when the car is pushed on track or modified for more power.

One such component is the rear differential cover.

Often overlooked, the factory aluminum diff cover plays a critical structural and thermal role. Yet, it was never designed for the kind of stress E30s face today in drifting, hill climbs, track days, or even spirited daily driving with sticky tires and upgraded engines.

Understanding the Function of the Differential Cover

While its primary job is to seal the rear of the diff housing and retain gear oil, the cover also:

-

Holds the outer differential bearings in place

-

Supports internal alignment under torque and heat

-

Affects how well the oil stays cool under continuous load

The OEM cover, being made from relatively thin cast aluminum, has a tendency to flex and distort, especially when heat builds up or the car is cornering hard. Over time, this can lead to:

-

Oil seepage

-

Accelerated bearing wear

-

Reduced gear life

-

Misalignment of internal components

Heat: The Silent Killer in Differentials

Differentials naturally generate heat—especially when used aggressively. The E30’s OEM cover has limited cooling capacity, and its internal volume for oil is minimal. Unlike modern performance cars that feature finned or reinforced diff housings, the E30 relies on passive cooling through a small, smooth surface.

When temperatures rise too high, gear oil loses viscosity, and wear accelerates dramatically. This is one reason why some E30 diffs fail prematurely, especially in motorsport environments.

The Billet Aluminum Solution

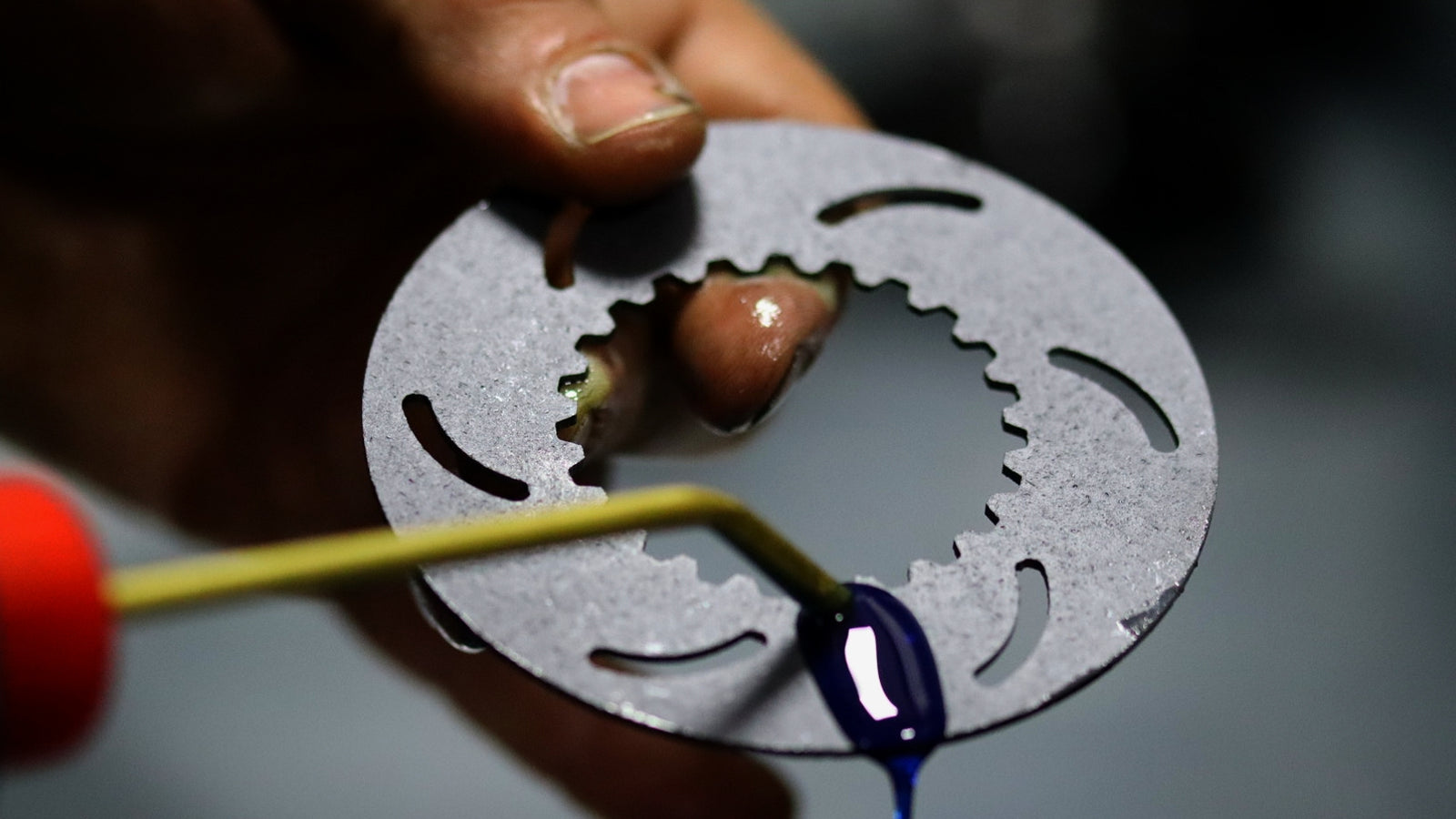

Upgrading to a CNC-machined billet aluminum differential cover addresses both strength and cooling deficiencies. These covers are typically milled from a solid block of aluminum, eliminating porosity and flex issues associated with cast components.

Key functional benefits include:

-

Reinforced structural rigidity

-

Increased oil volume

-

Finned exterior for passive cooling

-

Stable bearing support under high torque

These improvements directly impact long-term reliability and performance consistency, particularly when the car is used in high-stress conditions like drifting, rallying, or endurance racing.

Real-World Testing and Engineering Insights

In our case, the development of the billet cover for the E30 diff came as a response to failures observed on drift cars and customer vehicles. After reviewing damage patterns—especially around the bearing seats—it became clear that flex at the rear cover was contributing to failure.

You can see more about this in our development video, where we showcase the differences in design and field testing on the RacingDiffs E30 drift car.

Compatibility and Fitment

While this discussion centers around the BMW E30, it’s worth noting that this upgrade applies to any vehicle using the 188mm medium-case differential. That includes many models in the E30, E36, and Z3 family.

When Does It Make Sense to Upgrade?

Not everyone needs a billet cover. But if any of the following apply to your E30, it’s worth serious consideration:

-

You use the car for drifting, time attack, or hill climbs

-

You’ve increased engine torque significantly

-

You’ve experienced rear diff leaks or bearing noise

-

You want to future-proof the drivetrain for hard use

For those building a long-term performance platform, the billet rear cover isn’t just a visual or luxury mod—it’s a structural improvement backed by real mechanical logic.

Also in News

BMW Differential Types Explained: Sizes, Generations and Housing Codes

February 24, 2026 5 min read

Read More

Think Welded Diff Is Enough for Drifting? Think Again. Here’s the Truth.

December 15, 2025 4 min read

Read More