Apparel

Accessories

Check out our full lineup of yoga accessories to help you with your daily meditation practice and fitness goals...

Try our new Cork Yoga Brick for soft but solid support

Check out our full lineup of yoga accessories to help you with your daily meditation practice and fitness goals...

Shop

Mega menu

tetasidjaslkihsdlkjfhsdf gjkhsdfgjklsdhfgjkl shdfgjklhsdfgjkl hsdfjklg hsdfkjlg hsdfjklg hsdfjkl ghsdfjkl ghsdfjklgh

Mega menu

Time to get excited about our new collection for Men!

tetasidjaslkihsdlkjfhsdf gjkhsdfgjklsdhfgjkl shdfgjklhsdfgjkl hsdfjklg hsdfkjlg hsdfjklg hsdfjkl ghsdfjkl ghsdfjklgh

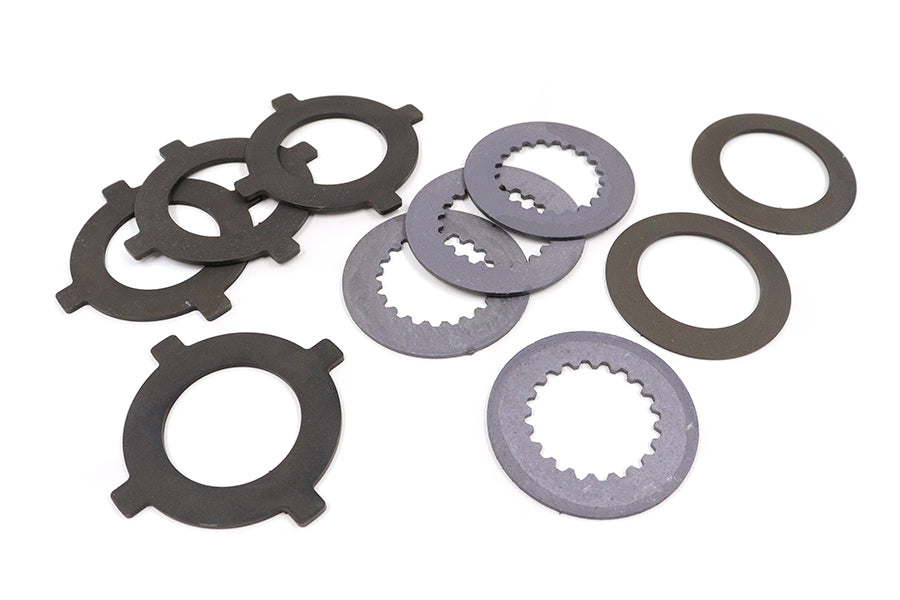

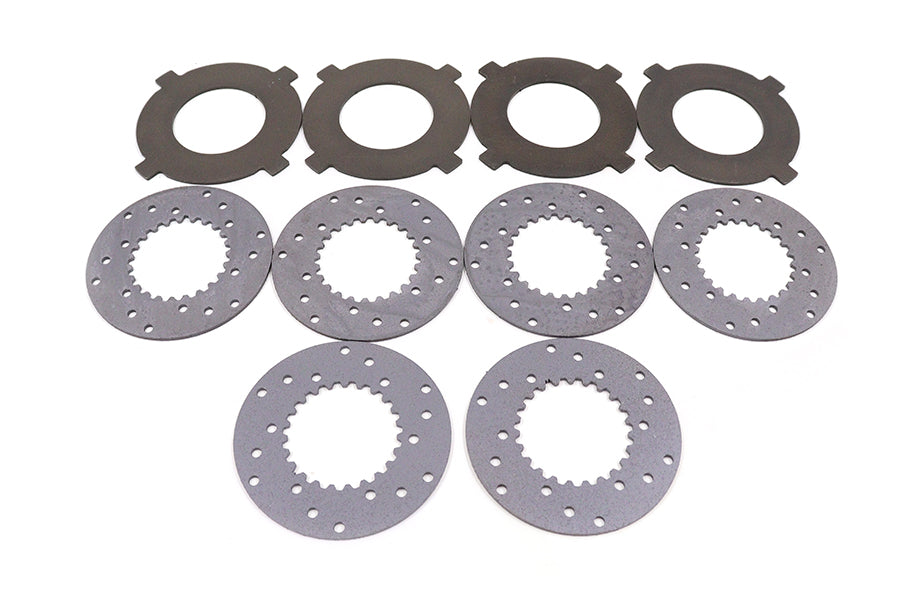

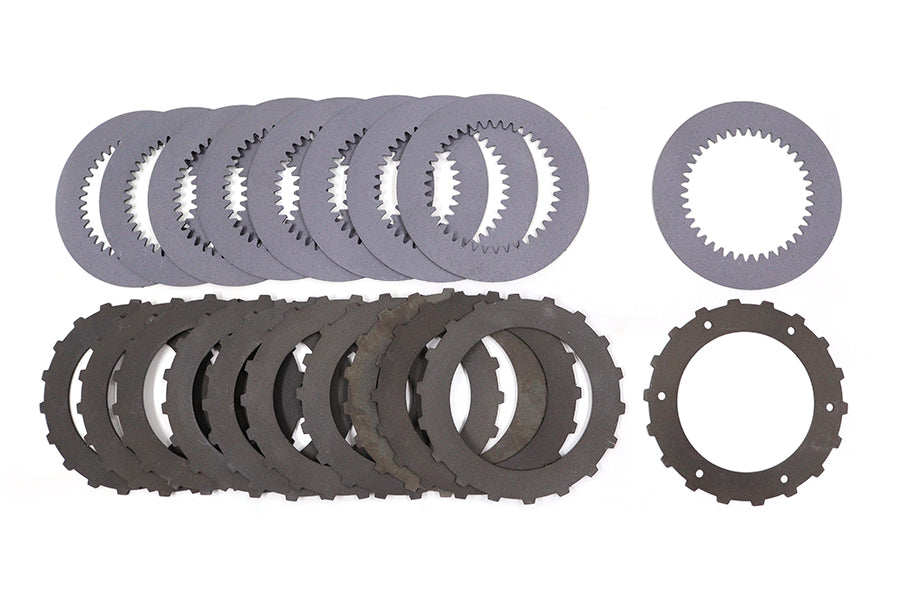

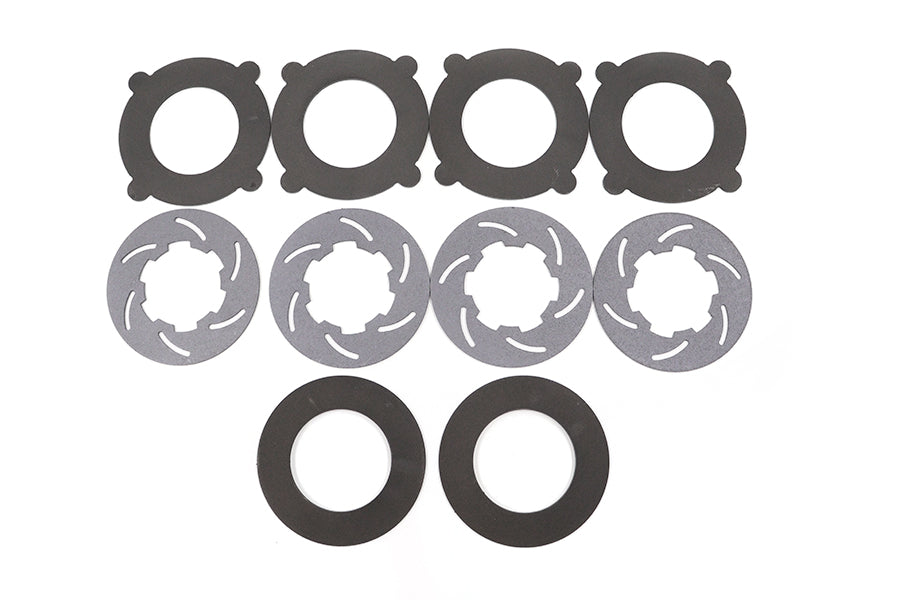

How to know if your Limited slip differential (LSD) needs a rebuild?

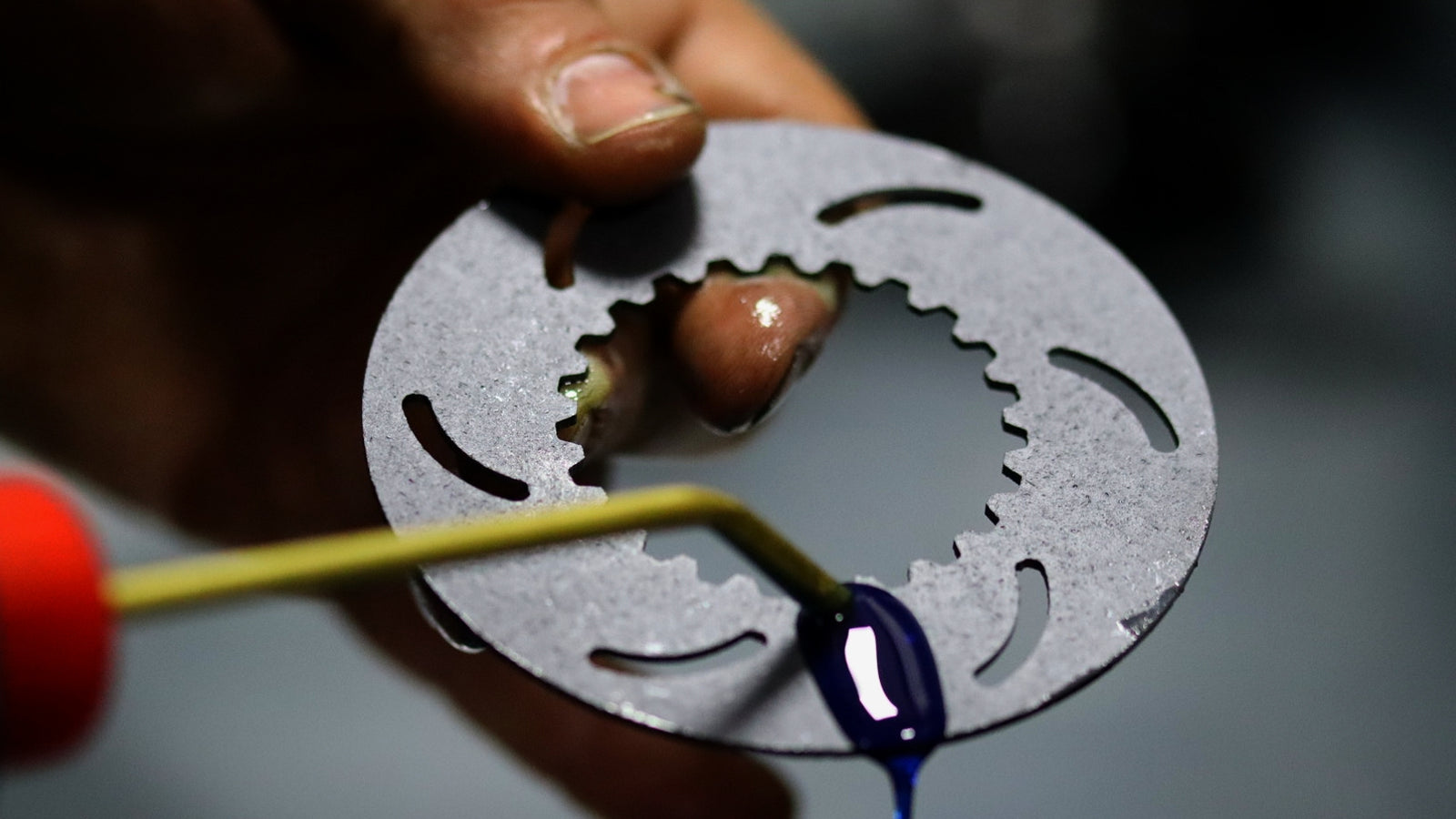

Worn clutch plates inside the LSD unit is the main reason for malfunctioning. Of course, visual inspection and measuring the thickness is the best way for checking the condition of clutch plates, but there is another, faster and simpler way.

Breakaway torque test will indicate the condition of LSD components without disassembling the differential. It is not even necessary to remove the differential from the car. You just need a precise torque wrench and flange adapter. Check the video tutorial on how to do breakaway torque test properly. If you measure less than 85% of the factory torque setup, than you should look into replacing Clutch plates.

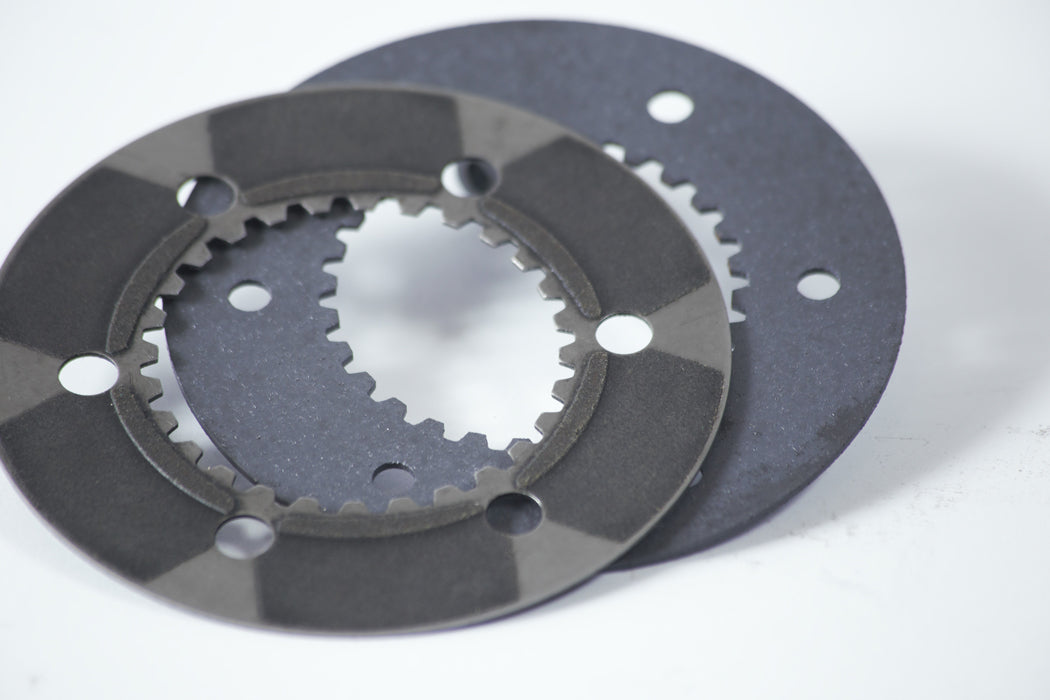

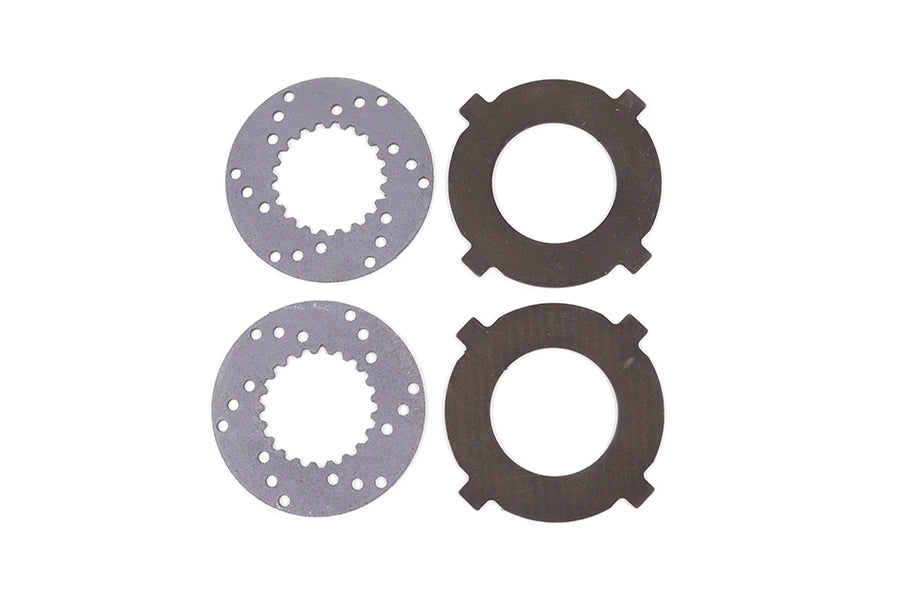

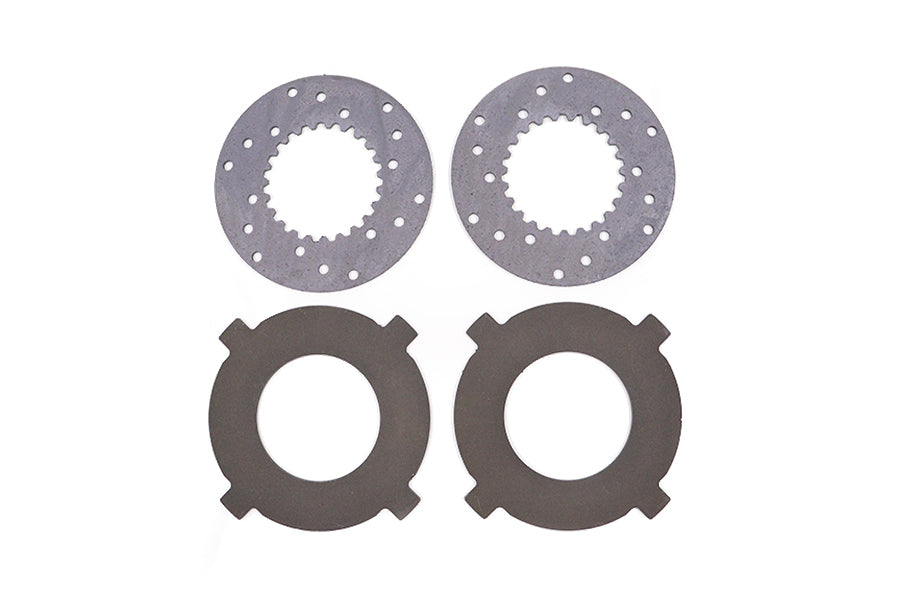

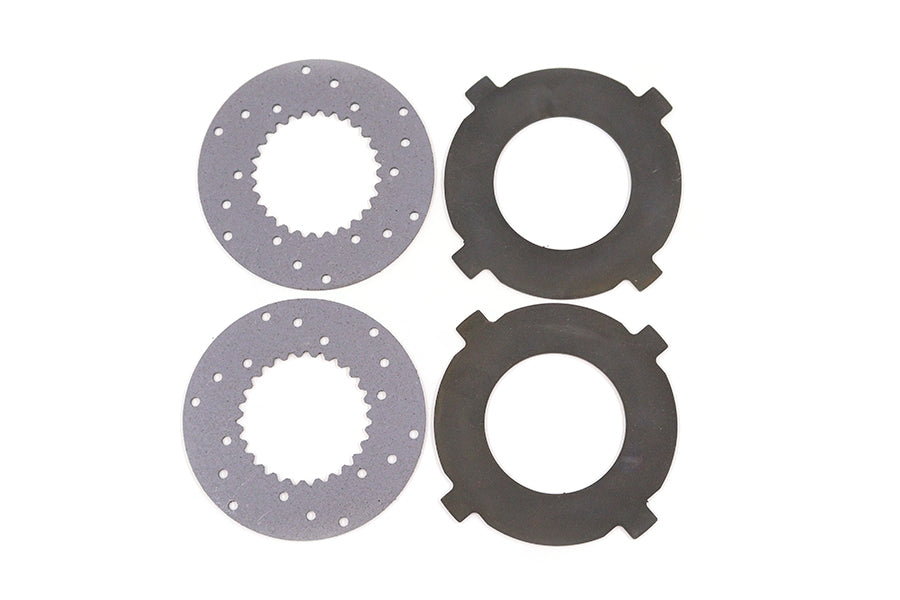

RacingDiffs Friction Plates for

OEM Limited slip differential (LSD)

are the most superior on the market. We use the highest quality thermally processed tool steel, which differentiates our products. During the final production stages, clutch plates are coated with special Molybdenum-Ceramic compound for the best ratio of friction coefficient and durability. This drastically reduces material wear and warping under extreme conditions, affording our clutch plates the best possible longevity.

Advantages:

- Higher friction coefficient

- More grip

- Increased diff lock

- Maximum durability

- Minimum wear

- Superior heat resistance

All of our Clutch Plates are thoroughly tested and are currently being used in a range of racing cars and disciplines throughout Europe and USA, including track, hill climb, rally, and, of course, drifting. You can find them in race cars of Michael Essa, Formula drift champion and Bisi Ezerioha (bisimoto), world recognized tuner.

We are the market leader for LSD friction elements, offering the highest quality products at the most affordable prices to the global driving community.

In addition, we offer custom production of plates, so if you have a specific request, please contact us for a quote.